Download mount preselection software

Paulstrasoft software allows you to determine the anti-vibration solution that meets your expectations.

Download

Screens produce high dynamic forces (forced vibrations and shocks) and movements to perform the product sorting function. These machines are therefore major sources of vibration and mechanical wear.

In our range of suspensions, Paulstra offers products that can provide both a durable and optimal operation of the screening process, while preserving the structure from mechanical stress.

A screen is a machine, used in many industrial fields (food, pharmaceutical, quarries, foundries, recycling, etc.), which filters and sorts solid materials according to their size. This industrial machine has a triple objective:

There are different types of screens (scalping screens, screen cloth excitation, pneumatic screens, dual-frequency screens, multi-deck screens, wet screens, flush and drain screens, etc.). Let's review the main machine models.

The scalping screen is usually two-deck and is located upstream of a crusher into which it will send the unsorted material. This machine, which is used for sorting coarse materials, consists of a reinforced rigid body, mounted on springs that enable it to withstand the shocks associated with receiving heavy or large items. The vibration of the scalping screen body is due to an unbalanced mechanism.

A pneumatic screen is a machine usually used to separate fine products from the chemical, pharmaceutical, recycling or food industry. This equipment works in the same way as a direct exciting screening machine (a static box and a sorting motion by high-frequency oscillations), supported by a pneumatic system.

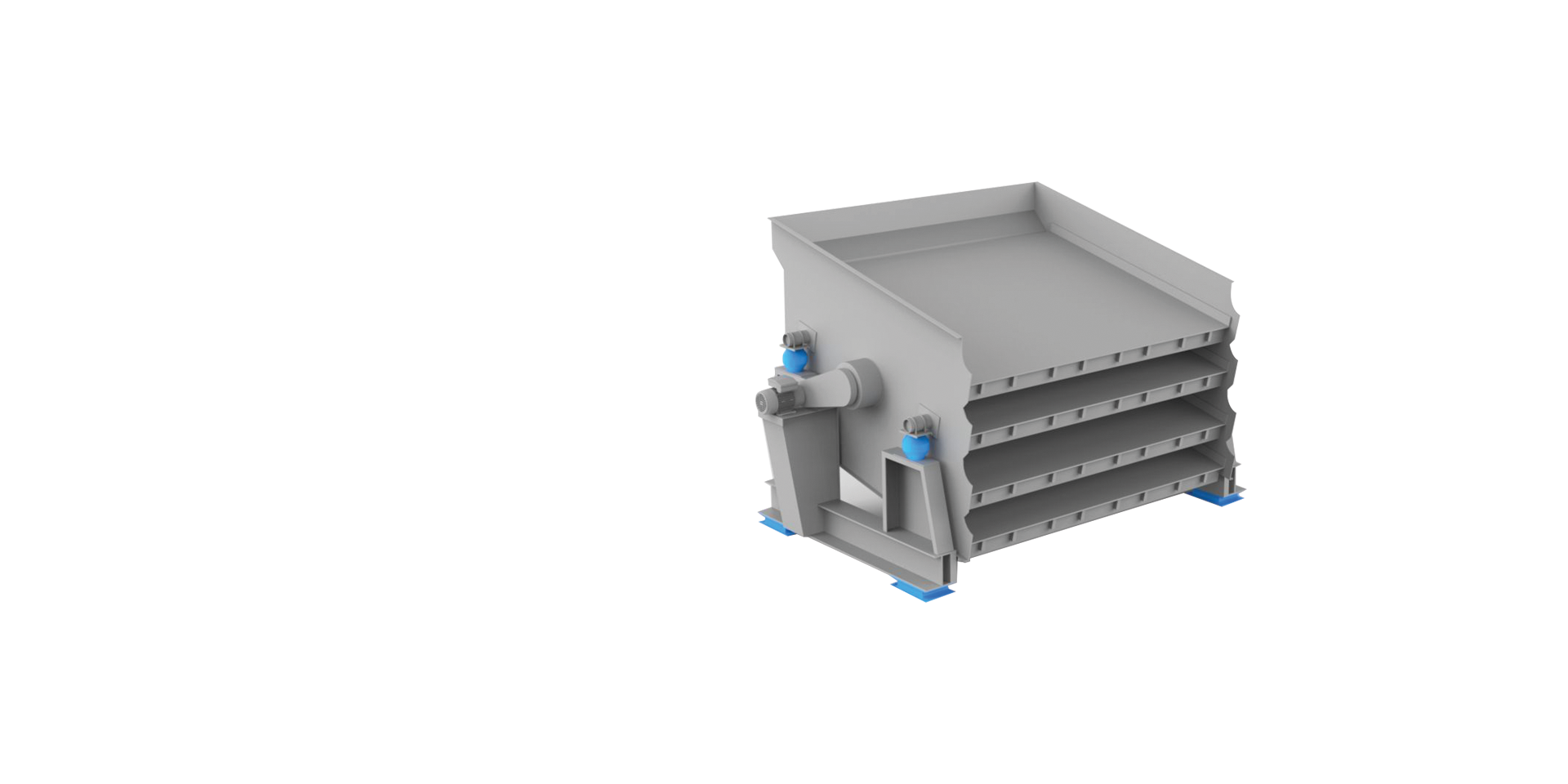

Multi-deck screening machines are particularly effective for the precise separation of medium to fine-grained materials. The products to be sieved pass through the screen decks, which are distributed from the largest grain size (top) to the smallest (bottom).

Paulstra has developed a complete range of vibro-acoustic solutions to ensure the continued use of your company's screens. Handling the vibrations and shocks perceived by the screening machine helps to reduce early mechanical wear and tear as a result of its action.

The vibro-acoustic solutions developed and distributed by Paulstra are suitable for a wide range of uses.

Would you like to determine the most suitable references for your case? Contact us.

string(2) "en"