Download mount preselection software

Paulstrasoft software allows you to determine the anti-vibration solution that meets your expectations.

Download

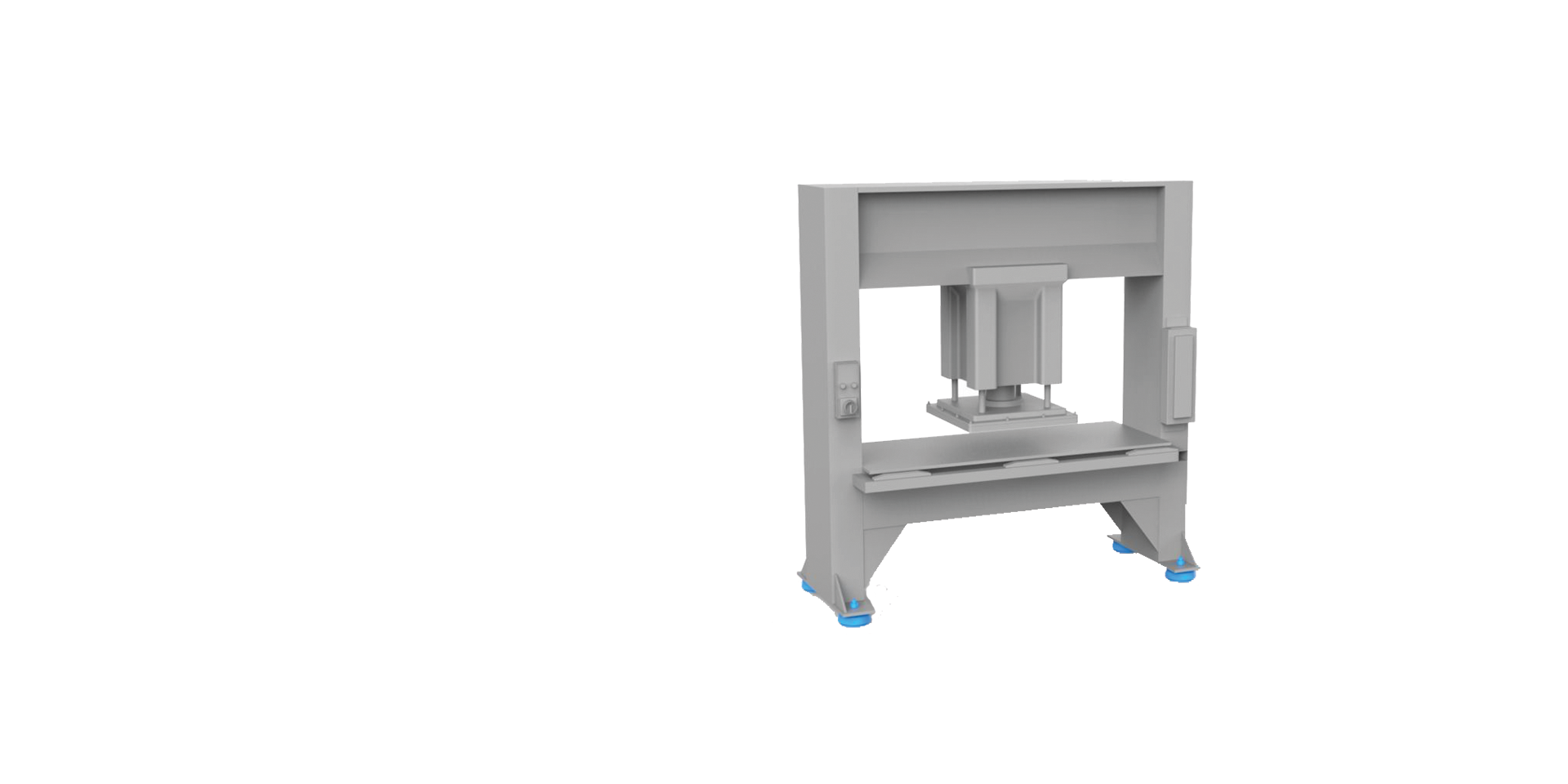

The various presses, shears, stamping or moulding machines generally generate vibrations that are harmful to their direct material and the human environment. It is therefore necessary to investigate the possibilities for effective isolation of impact and operating vibrations. With this in mind, Hutchinson Paulstra has designed a complete range of anti-vibration solutions and mounts.

Stamping and moulding machines, as well as presses and shears, are frequently found in industrial environments. These tools meet an almost universal need in the industry, regardless of the sector concerned. There are many models of presses and shears available for a variety of applications.

Industrial presses come in three families and can be used for a wide variety of tasks: punching, stripping, bending, stamping or riveting are dedicated applications. The mechanical press is a high-precision machine whose speed of operation allows the mass production of manufactured products. If it is set up quickly, an operator is required and therefore the mechanical press must be equipped with safety devices. The hydraulic press is ideal for small batch production and is capable of compressing absolutely all types of materials. The tool is also quieter than its mechanical and pneumatic counterparts, but more cumbersome and maintenance intensive. However, a properly maintained machine will very rarely break down and will be easily repaired. Lastly, the pneumatic press is a very versatile machine, rather used for small series is riveting, marking or crimping operations. As a result, they are commonly found in workshops and laboratories. They also take up less space than mechanical or hydraulic presses.

Industrial shears are used for cutting various materials for production purposes. There are three main models, present in different sectors of the industry. The guillotine shear is particularly used for cutting sheet metal and its motion controls are usually hydraulic. Lever shears are generally found in the mechanical and printing industries. The length of the shears is adapted to the thickness of the material to be cut. Lastly, rotary shears operate with circular blades whose rotary movement will drive the material to be cut. This model of shears allows very precise cutting and edging of various materials.

Presses and shears must be treated for vibration: they are very intense and generate significant vibrations that can be harmful to the direct vicinity, both material and human, of these industrial machines. In addition to prematurely damaging their functional elements, industrial shears and presses emit vibrations that can disrupt the proper functioning of other machines. The significant noise pollution from impact and operating vibrations can also be a source of discomfort for operators. It is therefore essential to consider the application of a vibro-acoustic treatment adapted to the machine and its application.

To effectively reduce the vibrations associated with the use of industrial presses and shears, Paulstra has developed a qualitative offer of elastomeric vibration mounts, metallic antivibration mounts, acoustic foams, elastic couplings and dynamic sealing solutions. Contact the Hutchinson Pausltra vibration and sound insulation specialists to carry out an audit of your needs in anti-vibration solutions and define the most suitable products according to your needs.

string(2) "en"